Vapor Intrusion

Vapor Intrusion (VI) occurs when volatile organic compounds (VOCs) migrate into a building from underlying contaminated soil and/or groundwater, resulting in potential health concerns for occupants. Stone has been conducting VI investigations and remedial planning for over fifteen years. VI investigation techniques are always evolving and Stone actively engages with state and federal agencies, equipment vendors, and other professionals to ensure we are at the forefront of the practice.

Our approach to VI sites includes four steps, which are further described below: assessment, remedial design, installation and start-up, and operations, monitoring, and maintenance.

Our Approach

Stone utilizes dynamic work strategies to rapidly move through these steps to minimize the amount of time building occupants are potentially exposed to contaminated air.

Assessment

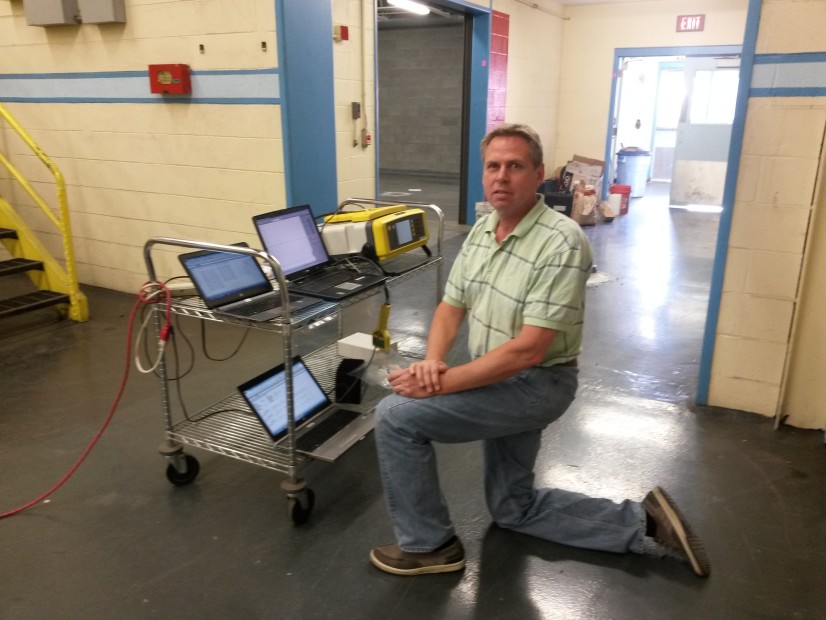

Assessments are designed to define the degree and extent of soil gas contaminants present at a site, potential entry routes into the building, and factors that may influence VI, such as building ventilation equipment and pressure differentials between indoor air and the sub-slab environment. Stone utilizes on-site laboratories, near-real-time analytical techniques, and/or rapid analytical turnaround times to move immediately from assessment into pre-remedial design testing. Vacuum field extension pilot testing is the most common test employed to quantify sub-slab vapor extraction rates at varying induced vacuums, which is used to optimize remedial system design.

Remedial Design

A remedial design can only be successful if the assessment provides a clear understanding of the degree and extent of contaminants, building construction, ventilation equipment, subsurface utilities, and pilot test results. There are no two identical buildings with identical VI conditions. As a result, no two remedial designs are the same. Stone’s remedial design packages typically include:

- A Scope of Work;

- Site Background Information, including a summary of assessment and pilot test results;

- Remedial System Component Specifications;

- Detailed Engineering Specifications;

- Technical Design Drawings;

- A Description of Installation Methods; and

- OM&M Requirements.

Installation and Start-Up

Stone has experience installing mitigation systems of varying sizes and operational capacities within residential and commercial settings or providing oversight for installation projects where it is more cost effective to subcontract labor to a mechanical engineering company. Oversight is provided to ensure that mitigation systems are constructed in accordance with the design specifications.

Startup monitoring is conducted to ensure the effective operation of the mitigation system. Airflow within multiple fan/multiple leg systems is balanced to distribute vacuum throughout the system and maximize the extent of the vacuum field. Operating parameters are measured to verify that the sub-slab environment is depressurized relative to indoor air, eliminating the potential for VI. Other adjustments are made to the system in order to ensure maximum efficiency and reducing electrical costs and premature mechanical failure.

Operations, Monitoring, and Maintenance (OM&M)

Stone develops site-specific OM&M plans following system startup. These plans detail inspection schedules and activities that are required to ensure the system operates within specific parameters for the duration VI mitigation is required. Stone provides remote monitoring services that can alert us to system failures and allow for immediate remedial steps. Reporting of OM&M activities follows state requirements.